With the growth of the global supply chain, warehouses are under the pressure of the need for ever better, faster and more efficient performance. Since this pressure is constantly growing, the role of slim warehouse management becomes increasingly relevant.

However, since the principle of lean management is relatively new in the storage industry, many warehouse managers do not yet have a right idea of it. Seton helps you to familiarize yourself with the matter and to expand your expertise. Seton also offers suitable lean solutions for their storage requirements and more effective management of your warehouse.

This:

What is lean management?

Toyota for the automotive industry developed the lean way. It aims to eliminate all activities or processes that consume resources, but do not generate any added value.

Lean management is a systematic method for reducing waste (“Muda”) without influencing productivity. It also aims to eliminate waste due to overload (“muri”) and due to inconsistency in the workload (“Mura”).

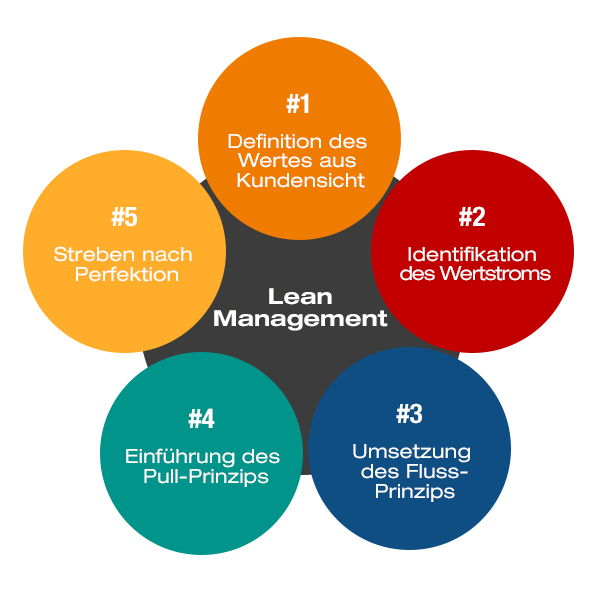

The basic principle of lean management:

- Definition of the value from the customer’s point of view

- Identification of the value current

- Implementation of the river principle

- Introduction of the Pull principle

- Striving for perfection

This: Made in Cologne © 2021: //digitalneulord.de/blog/leean-management/

Was it lean warehousing?

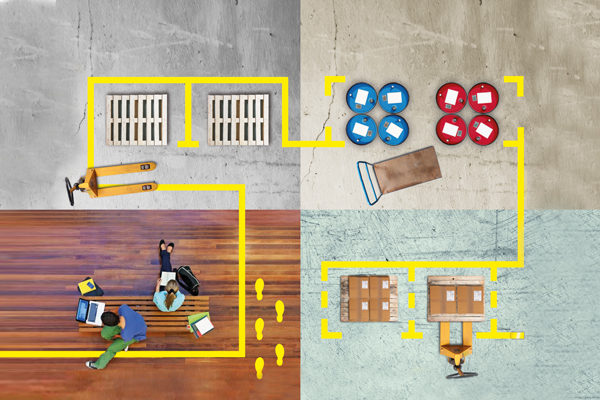

Modern warehouses are not only limited to storage. Since your processes include processes such as input, storage, picking and shipping, etc., the lean method is also applied to warehousing.

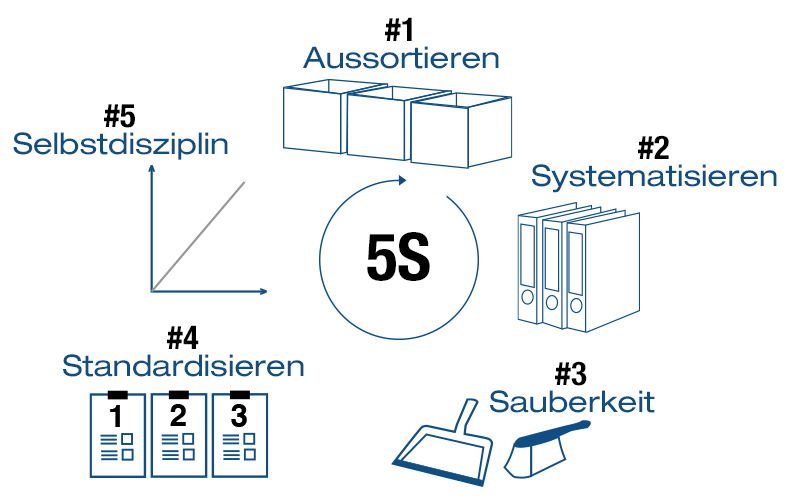

In the context of warehousing, it is about eliminating those processes and activities that absorb resources but do not create any additional value. This is done by using Lean’s 5S system on the processes and procedures of the warehouse:

What: © Alphadi 2021 //alphadi.de/5S/

Why lean for warehouse management?

Challenges that camp managers have to face every day

- Reduction of operating costs

- Coping with shorter throughput times

- Increasing the number of perfect orders

- Reaching the target of delivery on the same day/the next day

- High fluctuation rates and increasing labor costs

- Management of several delivery channels

- Management of an increasing number of ski

- Lack of space

- Seasonal/fluctuating requirements

And these are just a few of the challenges in which Lean management can help.

Goals that you can achieve with lean

While Lean leads to better efficiency, fewer errors and maximum system optimization on a broad level, here are some specific goals that you can achieve with lean:

- Standardization of the work processes, which leads to a shorter order processing period

- Optimization of system usage by finding the right space for the correct inventory/correct equipment

- Elimination of inefficiencies in material handling and thus reducing work and transport costs

- Bearing position as required, which means that seasonal demand can be easily mastered

- Reduction of time loss, which gives you a higher rate of perfect orders and deliveries on the same or next day

- Standardized processes that enable simple management and evaluation of several ski

- Better personnel management that leads to lower fluctuation rates

- Creation of space for new ideas and innovations, which leads to a constant improvement

Eliminate waste with lean management

- Interns transport – driving an empty forklift if it could be loaded

- Defects – Adjustments, incorrect assets, rework

- Stored stock – Overcrowded input and output areas, poor view of the inventory, storage of outdated stocks

- Material bearing and handling – not fully utilized areas, storage of the wrong material in the wrong place; Use inefficient and wasteful methods for material handling

- Movement (from people) – Interruption of the movement of warehouses due to the provision of goods before storage

- Waiting times/delays – bottlenecks at picking places, delays in shipping shipping

- Overproduction – hold more inventory than necessary; Implementation of unnecessary activities such as labeling and control if they are not needed

- Ignore the creativity of the employees – Ideas and innovations are not welcomed, which hinders growth and reduces the work ethic

- Overengineering – use of a complicated process/complicated equipment where a easier process can be more efficient

Application of lean in the warehouse

Lean management works in the warehouse with the 5S systemwhich was originally taken over from slim production. It is a comprehensive method that systematized, cleaned and organized the warehouse and standardized.

The original 5s of Lean:

This:

1. Sort the first S – Seii –

Sorting out the camp is the first step. Disconnect things you need from those that you don’t need.

How to sort:

- Removing unnecessary things such as damaged/outdated stocks, excess stocks, broken pallets, defective devices, etc. is a good way to solve the problem of the shortage of space.

- You can also consider reducing or ending unnecessary movements, for example by setting up a cross-speed within the picking area in order to effectively reduce the driving time of the operators.

- The replacement of manual paper communication with technology such as scanner or voice picking etc. can largely remove wasteful activities.

- Mark the items that need to be disposed of and keep them in a separate place until the approval for the final disposal is obtained.

2. The second S – sideways – systematized

The sorting should follow cleaning up. Decide for a way to organize things so that efficiency is increased.

How to clean up:

- Place frequently used items in more easily accessible areas.

- Enter inventory signs and labels on warehouse and containers to save time when finding articles. Seton supports you in inventory with numerous products for storage labeling.

- Enter warehouse signs and instructions to improve the organization and make it easier for warehousing to orientate what time reduces the time.

Seton simplifies your warehouse organization with many practical articles - Install soil and gear markings to improve pedestrian traffic and avoid confusion. Seton helps you with the floor marking with many proven floor coverings

- Keep empty pallets and packaging in one place that can be easily accessed if necessary.

3. The third S – seiso – cleanliness

This S stands for cleaning or cleaning the workplace after work. A schedule must also be observed for this.

This:

How to ensure cleanliness:

- Let all work areas clean at the end of the layer. In this way, any defects or damage can be reported immediately. You can find diverse cleaning utensils for the cleanliness of your warehouse.

- Before each gear, set up trash can to ensure that there is no packaging paper, broken pallets, etc. lying around.

Also provide basic equipment on cleaning agents and instruments. Keep outlet sets ready for the case that something is accidentally spilled or scattered in the corridors. Seton offers optimal solutions for waste disposal.

4. The fourth S – Seiketsu – standardize

Uniformity can only be achieved through standardization. The creation of standards for all work areas in the warehouse is essential. This requires the fourth S. At Seton you will also find storage bags for documenting process standardization.

How to standardize:

- Go through every process with the employees and document the best practices and processes in warehouse operations.

- Make standardized processes and procedures accessible and visible to employees.

- Keep the presentation of these methods easily understandable and striking.

- Use posters and diagrams that are more memorable because there is more to see and read less.

- Implement training manuals and videos as a good way to instruct new employees into the follow -up of the standards and at the same time save time.

5. The fifth S – Shitsuke – self -discipline

A continuous improvement of the processes, procedures and processes in the warehouse is essential. Standardization is ineffective if it is not maintained.

How to achieve Sustain:

- Encourage employees to accept changes, bring improvements to a new level and not return to old standards.

- This paves the way to the Kaizen principle, which says that change is good and things always have to be improved.

- Perform regular audits and controls to ensure that the standards are observed.

- Set incentives for high performance with a bonus and leisure.

- Take into account creative and innovative ideas from employees.

- Be open to the creation of new standards if the current standards are not proven

6. The sixth S* security

Increase the safety of your employees in the warehouses, which means that you can also avert litigation by preventing accidents.

How to ensure security:

- Perform a risk assessment at regular intervals.

- Check the layout and design of the warehouse with regard to safety, including factors such as walking paths, ramps/stairs, shelves, escape routes, etc., and make necessary changes.

- Have a fire and emergency plan that includes the following:

- Fire/emergency exits and evacuation procedures

- Location of fire extinguishers and emergency water hoses

- Persecution of all visitors and employees who are at the location at a certain point in time.

The correct labeling with Describe Security increases from Seton.

The correct labeling with Describe Security increases from Seton.

Are you responsible in your job for warehouse management or lean warehouse management? Register for our newsletter and receive valuable tips!

Also worth reading and appropriately: Our contribution to the topic of accident focus warehouse: 10 tips on how to prevent serious accidents

Дезинфекция в СПб! Комнаты, Особняки, Бизнес-центры. Безупречный услуги чистоты по демократичным тарифам. Освободите свой график! Оформите заказ приборку немедленно! Кликайте https://kliningovaya-uborka-spb.ru – СПб клининговая компания